Origin and Physics of Noise

In this section it is described what noise is, how to quantify it, and how Levitronix Bearingless Fan Systems generate it.

Physics of Noise

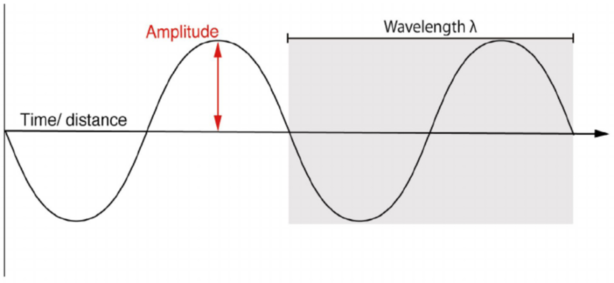

Noise is a periodic perturbation of the air, a pressure wave, characterized by

- Wavelength, measured in meters (m)

- Frequency, which depends on the wavelength, measured in Hertz (Hz = 1/s).

- Amplitude, measured in Decibel, a log scaled value of the amplitude relative to a standard reference. This is an expression of the “loudness” of the noise.

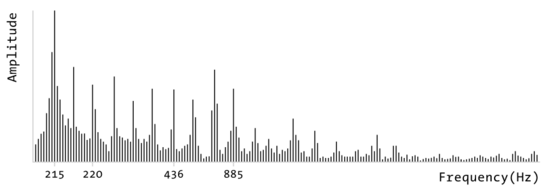

Machinery typically creates noises at various frequencies, each having its own amplitude. Summing up the amplitudes of all frequencies provides an overall level of noisiness of a machine.

Sources of Noise in a Levitronix BFS

There are two main sources of noise in a Levitronix fan system:

- Aerodynamic, due to air interacting with the fan, it’s the dominant source at high rotational speeds

- Electro-magnetic, due to the magnetic interaction between stator and rotor, it’s the dominant source at low speeds.

Each source can generate

- Broadband noise (similar to loud white noise)

- Tonal noises (sounds at specific frequencies).

The broadband noise is for example generated when the incoming airflow is “cut” through by the fan blades, by the vortexes developing downstream of the fan and in the clearance around the wings’ tips.

Tonal noise is generated in a fan for example by the interaction of the blades’ wakes and the guide vanes at the outlet. The frequency of such interaction depends on the number of blades and guide vanes, as well as the rotation speed. The product of these three parameters defines the Blade Pass Frequency. As a result, the typical sound spectrum of an axial fan looks as in Figure 3.

Other sources of tonal noise are for example due to non-uniformity of the flow profile (once again, the tonal frequency will depend on the rotational speed and on the number of blades).

As shown in Figure 3, the tonal frequencies present the highest amplitudes, therefore they are louder than the broadband noise, and they are the major contributors to the overall fan noise. Since the BPF increases with the speed, the higher the speed the higher the pitch of the fan noise.

Noise Perception and Adjusted Levels

The noise frequency range is very extended (from a few Hz to MHz), but only the frequencies between 20Hz and 20kHz are audible by humans. Even within this range, frequencies around 1kHz have the lowest threshold (meaning that even at low amplitude can be heard by humans), while lower and higher frequencies have higher thresholds (a moderately loud noise might not be perceived by a human, if the frequency is far from 1kHz).

When discussing noise in human environment (i.e. for safety assessments and regulations compliance), an “adjusted” sound level is used. Adjustment is performed by measuring the intensity of the noise at each frequency, subtracting a standardized weighting factor (which depends on how humanly audible that frequency is), and summing up the adjusted amplitudes over the whole frequency span. The resulting value is then expressed in dBA (decibel adjusted), and it’s the common equipment sound specification provided by manufacturers.